SPL GROUP

Safety

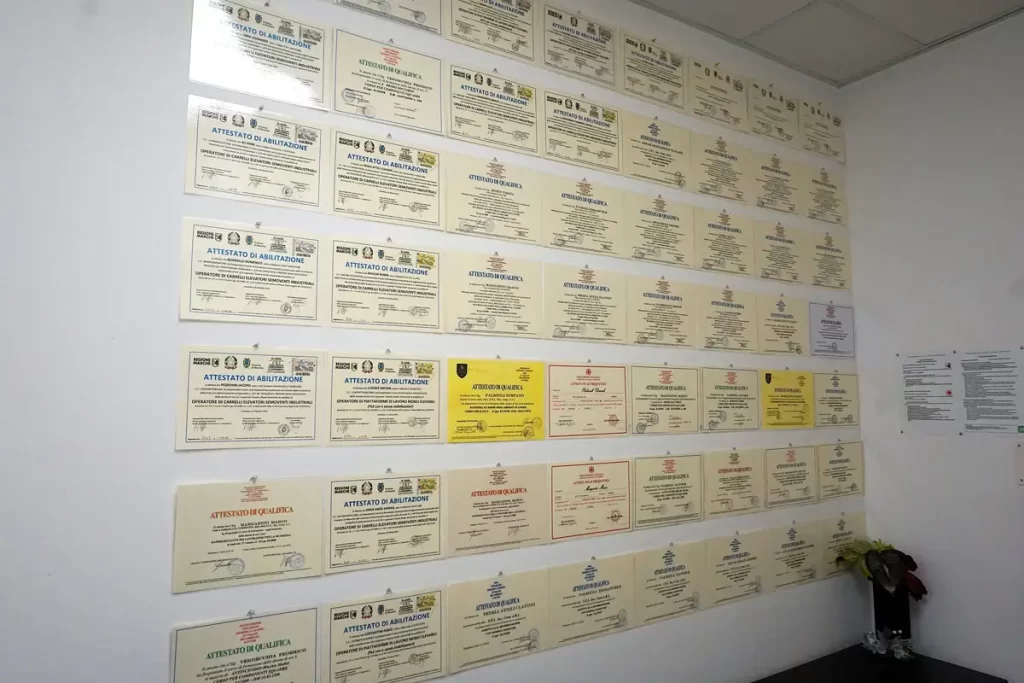

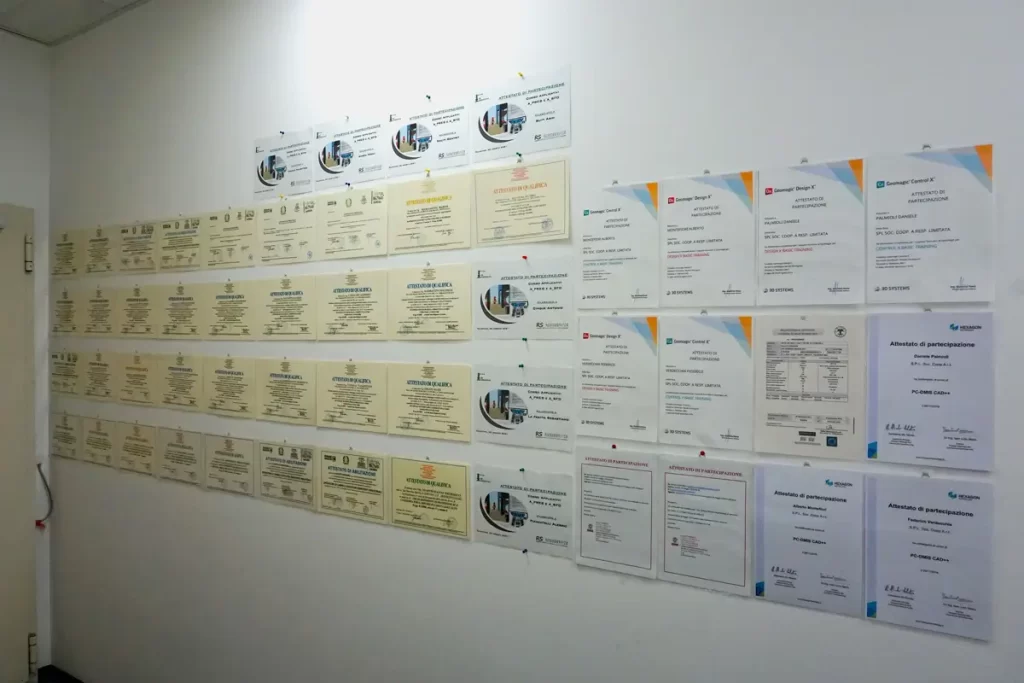

Safety and Training

The only path to follow to be an innovative company.

The safety of our employees is a top priority. We work continuously to create a safe and secure environment, adopting strict measures and advanced technologies to prevent any risks. We invest in the ongoing training of our staff and in the maintenance of our facilities to ensure a safe workplace where every team member can operate with peace of mind and responsibility.

We have embarked on the voluntary path of UNI EN ISO 45001 to proactively improve performance related to health and safety at work, involving all workers in this process.