Mechanical Solutions

Looking to the future, we aim to develop and supply welded mechanical components and machined parts by leveraging the synergy between engineering, tool manufacturing, and stamping.

Additionally, we provide series parts machined by CNC, and where required, we perform the pickling and washing processes of the components in-house.

Groups and Subgroups

Production milling

Washing and pickling of components

Production milling

SPL Tech Solutions specializes in production mechanical machining of steel, cast iron, and aluminum components.

We use well-designed processes and well-structured equipment manufactured internally to ensure maximum reliability and precision of the components. The activities are supported by 24/7 quality control to assist the operations.

Steel processing

Cast iron processing

Aluminum processing

Parpas ML90 5 axis-8m

Single-cloumn Gantry CNC Machine Parpas ml90 - 5 axis

Travel: 8000 x 2000 x 1500

Tool capacity: 12 slots

Table surface: 9000 x 2000

Spindle: 5-axis, reaches up to 6000 RPM

Rema Control Leonardo Big

CNC Machining Centre Rema Control Leonardo Big

Travel: 3300 x 1200 x 1200

Electrospindle Kessler: 10000 RPM

Tool capacity: 50 slots

Rapid traverse speed: 50000 mm/min

Awea

CNC Machining Centre AWEA

Travel: 2000 x 1200 x 760

Tool capacity: 32 slots

Spindle: reaches up to 8000 RPM

Washing System

- Pre-wash at 50°C

- Washing at 50°C

- Drying at 45°C

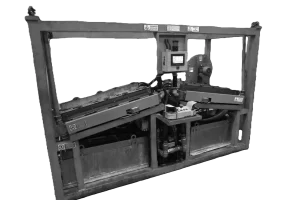

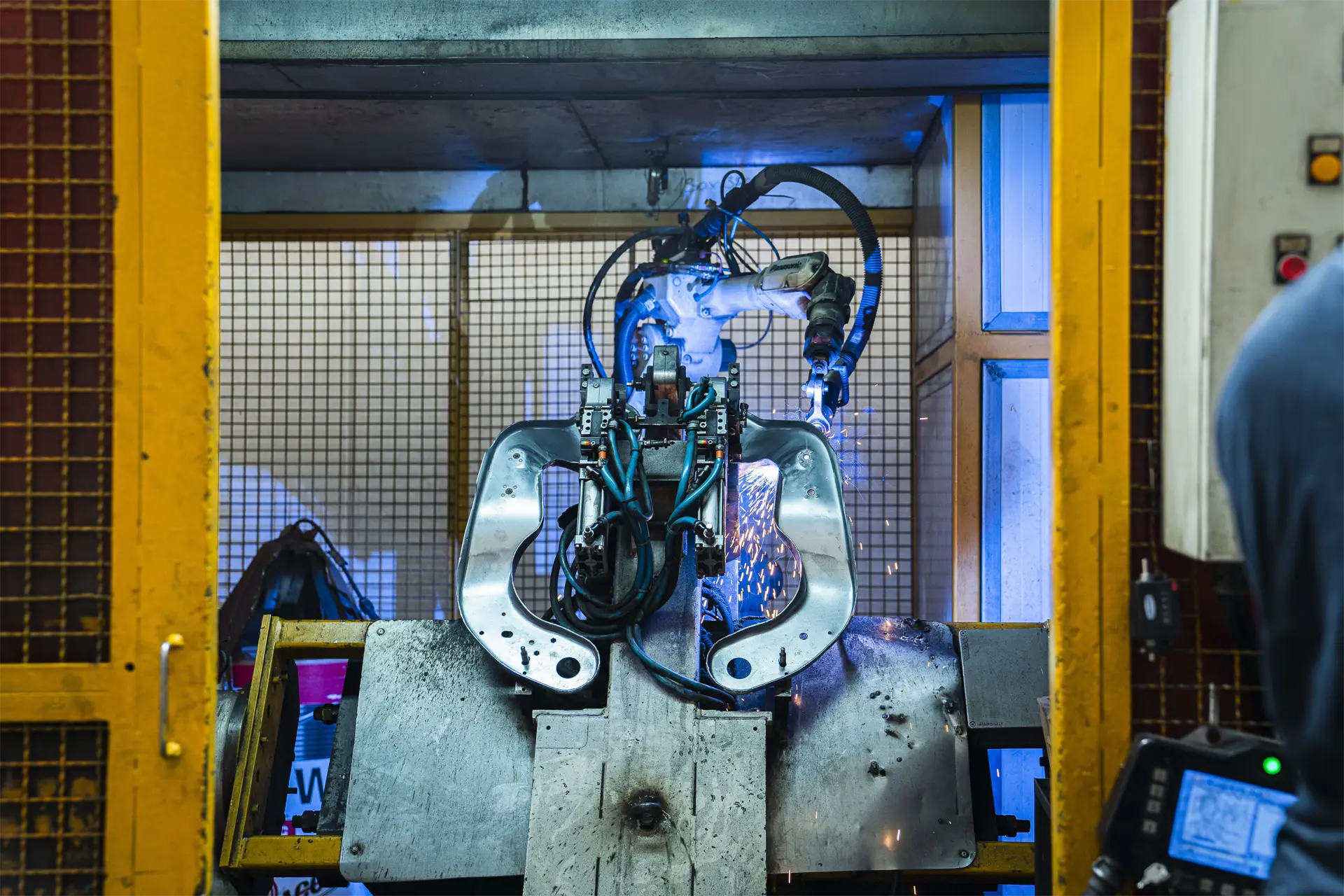

Robotic Welding

Manual Welding

Robotic and Manual Welding

We have a robotic welding system and qualified personnel, equipped with welding licenses, thus being able to certify our welds.

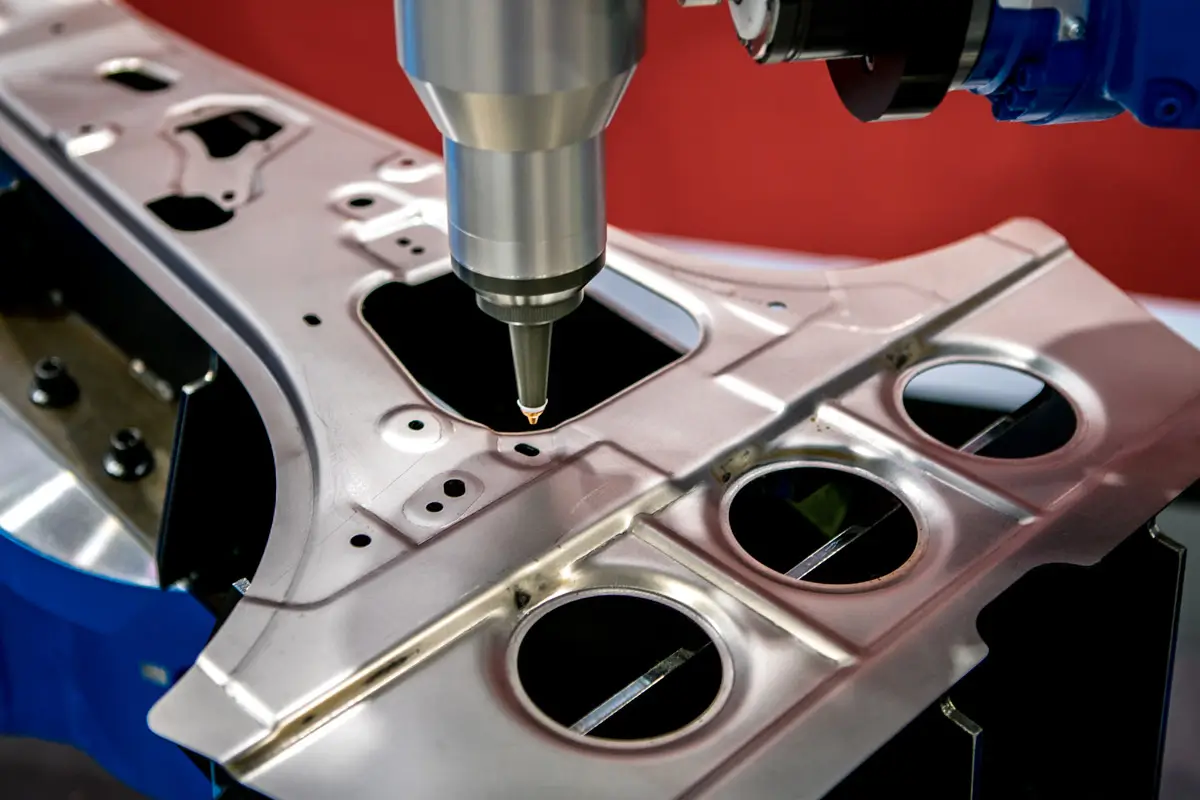

Laser Cutting and Bending

With a well-established network of local collaborators, SPL Tech Solutions is pleased to further enhance its processes by offering 2D-3D laser cutting and bending services.

2D laser cutting

3D laser cutting

Bending

Coatings

To extend the lifespan of the component and increase its resistance to external factors, we offer various coatings including Painting, Galvanizing, and Cataphoresis, thanks to our collaboration with well-established companies in the sector.

Painting

Galvanizing

Cataphoresis

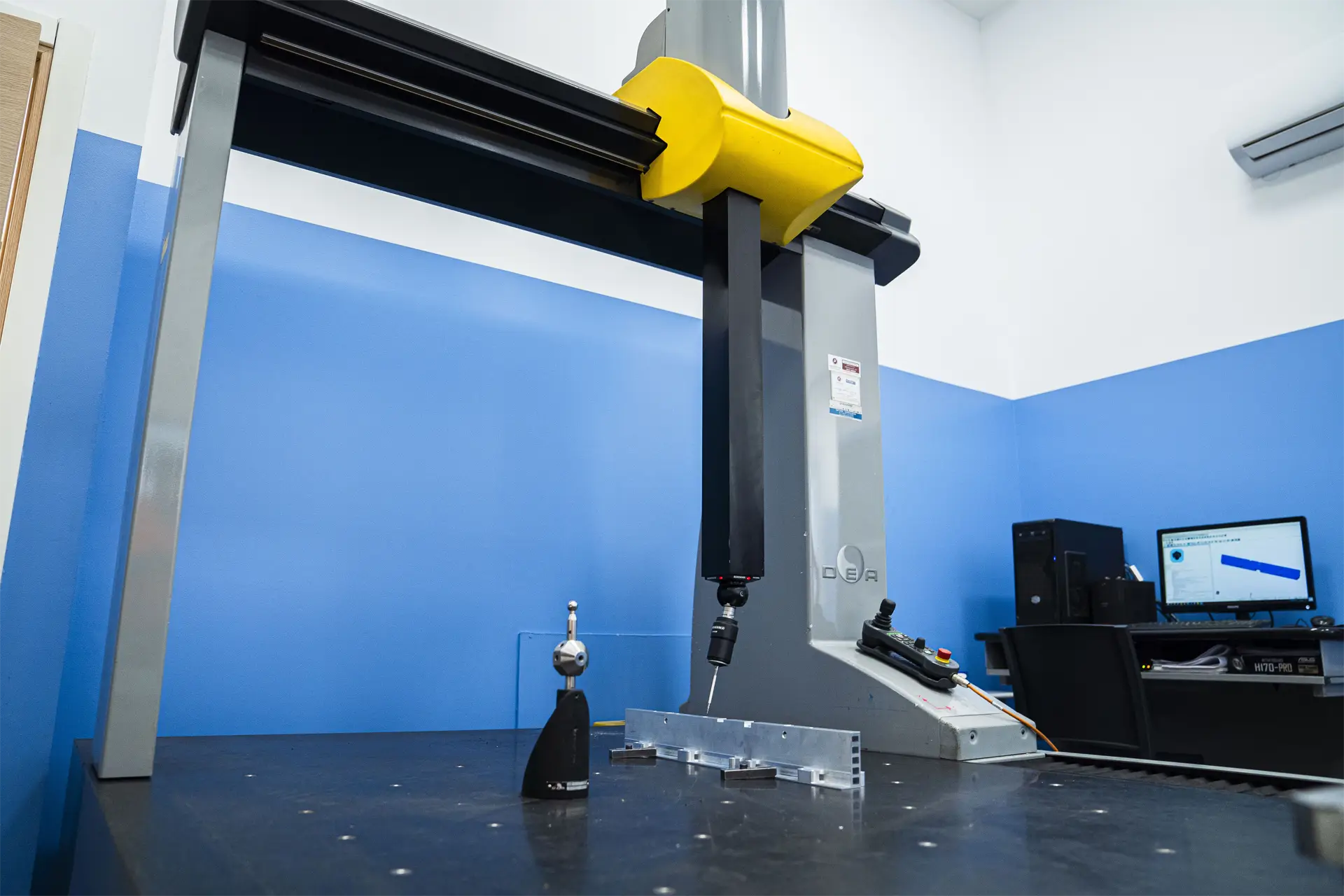

Quality Laboratory

In the current market, the Quality factor holds a primary and increasingly important role. Our quality department relies on state-of-the-art equipment, such as the measuring machine and laser scanners, to ensure component measurements and CP-CPK statistical controls.

Measuring machine cmm - dea global image

Measuring machine cmm - dea global image 12.22.10

* Granite worktable with anti-vibration pneumatic balancing

* Plane dimensions 3180x1400 mm, useful measuring volume 1200x2200x1000 mm

* Motorized automatic structure

* Thermal compensation system

* Point-to-point or continuous measurements (scans)

* Rotating head, complete with a wide range of tip styles/accessories

* PC-DMIS measurement software 2018 rev.

Exagon-absolute arm 7 axes

Exagon-absolute arm 7 axes

*Integrated RS4 scanner with 2.5 m measurement volume

* Zero Gravity counter balance with Smart-Lock

* Absolute encoders

*Digital camera and working light

* B89 certification

* RDS interface software

* “ControlX” quality control measurement software

* Quality control measurement software “ControlX”

Faro quantum scan arm 7 axes

Faro quantum scan arm 7 axes

* Quality control measurement software “ControlX”

* Reverse engineering measurement software “DesignX”

* Wifi connection

* Internal counterbalance system

Contacts

Fill out the form and send a contact request.

Our team of experts will reply to you as soon as possible.