SPL GROUP

The company

Vision

Mission

Working every day with and for our clients, offering them the advantage of interacting with a single point of contact and ensuring the fastest response times. Preserving the company values of fairness, transparency, and reliability to deliver product and service quality, while striving for constant technological innovation. We aim for a synergistic relationship between the company and the client, facing and overcoming the challenges of the future together.

The six pillars of S.P.L.'s mission I am:

- Seriousness and correctness: Fundamental to establishing solid and long-lasting relationships with our customers, based on trust and mutual respect.

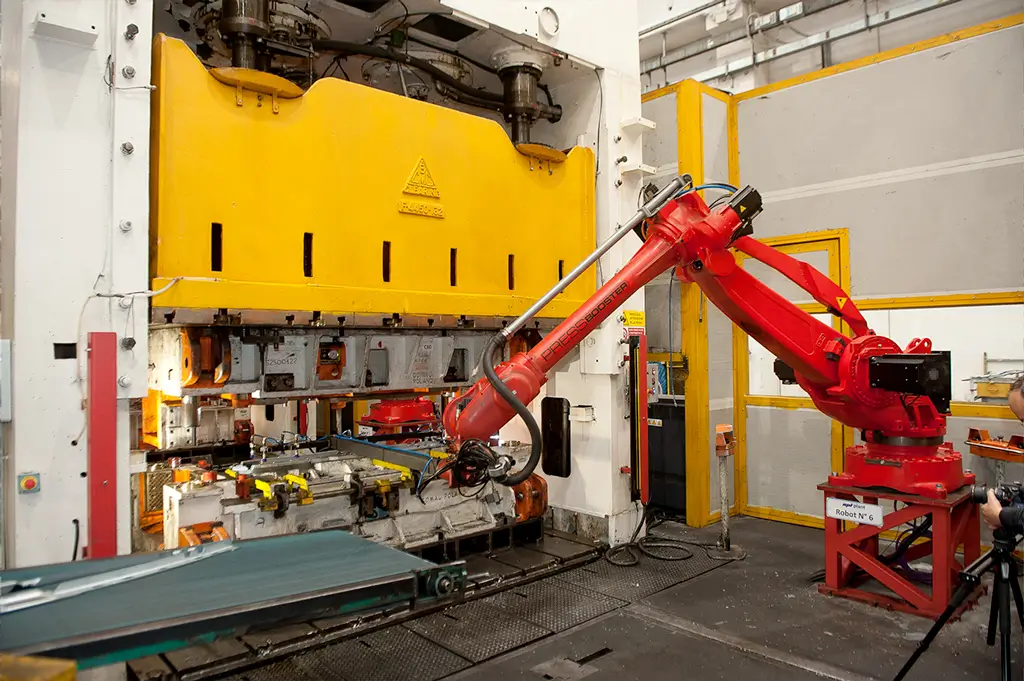

- Technology: We invest in cutting-edge machinery and automation to improve productivity, quality and efficiency, maintaining high competitiveness on the international market.

- Organisation: We value human resources through training and integrate processes with custom management software to ensure excellent service and 24/7 availability for production emergencies.

- Quality: We follow well-studied processes to offer products that meet customer specifications, reducing the costs of “non-quality”. We are working to obtain IATF 16949 certification, in addition to the already acquired ISO 9001.

- Efficiency: We aim to reduce production costs by investing in technology and optimizing business processes, seeing efficiency as the key to competitiveness.

- Safety: The health of workers and compliance with regulations are priorities. We invest in plant improvements and training to minimize the risk of accidents, aiming for ISO 45001 certification.

Our history

The founder, Sandro Palmioli, after gaining significant experience in Switzerland at watch manufacturing companies, was hired in 1962 at the FIAT Mirafiori plant as a specialized technician in the sheet metal stamping sector. His results were quickly rewarded with career advancement, as well as FIAT awards and recognition for his innovative technologies. Within a few years, he was transferred to the Technical Office for the design of large automotive tool dies, such as side panels, front and rear hoods, doors, fenders, etc. Before embarking on his entrepreneurial journey, he completed projects for the tool dies related to the side panels and doors of the Lancia Thema and Alfa Romeo 164, collaborating on design interventions with the renowned designer Giugiaro.

The origins of the company's business date back to 1987 in Tolentino, in the Marche region, following a very interesting proposal from the Merloni Elettrodomestici group, which saw Mr. Palmioli as a key figure for the automation of production processes. Initially, the work focused primarily on the design of automated stamping and assembly systems, leading to the development of systems for the production of the Margherita washing machine (drum and shell), as well as for stoves, cooktops, and refrigerators. However, soon after, the Ariston Group asked Mr. Palmioli to integrate the tool die construction activity within his company, along with the stamping production, thus becoming a supplier of sheet metal parts and components.

In the year 2000, the company saw the entry of Mr. Palmioli's sons, who, after completing their studies, enthusiastically embraced their father's entrepreneurial venture. The company's production horizons expanded to include the automotive, telecommunications, and truck markets. To meet the growing demand for work, large presses, robotic systems, and CNC machines were purchased for the production of sheet metal tool dies and internal automation. In just a few years, the company experienced exponential growth, reaching nearly 40 employees and receiving the prestigious "L'Italia che Lavora" award.

S.P.L.'s mission is to provide the customer with a complete package for sheet metal production, which includes:

• Equipment design (tool dies and production automation)

• Equipment and plant construction

• Production (stamping and assembly)

• Product certification through a quality laboratory

• Delivery to the customer (including just-in-time management)

In 2011, S.P.L.'s production activity was expanded to include the construction of sheet metal tool dies and automation systems for third parties.

In 2014, amidst significant company growth and an expanding client base, S.P.L. acquired a recently constructed industrial plant, much larger at 4.500 square meters, located in a strategic position within the industrial zone. Its proximity to the highway exit provides the company with easy access to the major road networks in Italy.

In 2015, the company's activity saw further growth, and the installation of new machinery created the need for additional space. As a result, the purchase of a second industrial plant of 2.700 square meters, adjacent to the existing one, was approved to be used as a warehouse.

In 2017, a third plant of 500 square meters was acquired, dedicated exclusively to personnel areas.

A second robotised press line with a total capacity of 2.000 tons was installed, equipped with a double loading station; this system allows us to competitively manage all the dies assigned to the 2.000-ton transfer.

In 2024, 14.000 square meters of industrial land adjacent to the current plant were purchased, intended for the construction of a new 8.000 square meter facility.