Sheet Metal

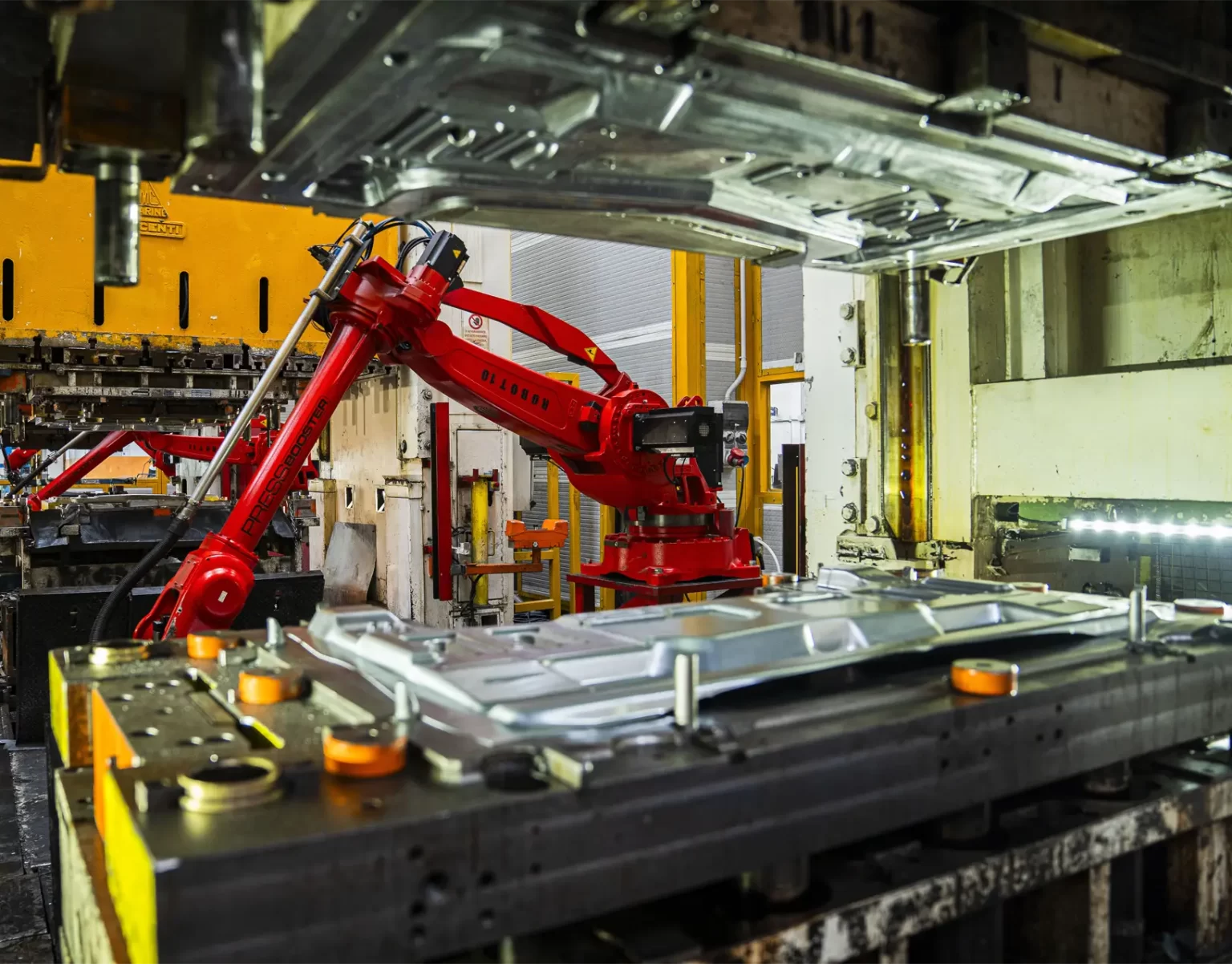

Our Sheet Metal division specializes in cold sheet metal stamping and offers a wide range of robotised presses supported by coil feed lines. We are capable of producing complex components with precision and reliability for various industries, including automotive, heavy transportation, home appliances, HVAC, and more.

Components Sector

Automotive

Components

Home Appliances-Air Conditioning Sector

Presses

The main activity of SPL Industries is cold stamping of sheet metal using coils and/or strips.

Our stamping department is equipped with 13 large presses supported by state-of-the-art 6-axis robots and coil lines up to 1.500mm in width.

We specialize in transfer, tandem line, blank cutting, and manual tool dies.

4000 ton press line tot.

N°1- 800 ton head press with 100 ton pneumatic cushion

•max height: 1430 mm

•min height: 1240 mm

•dim. Table: 3350x2130 mm

N°1- 1000 ton head press with 400 ton hydraulic cushion

•max height: 1498 mm

•min height: 888 mm

•dim. Table: 3360x2130 mm

N°4- 500 ton intermediate presses

•max height: 1350 mm

•min height: 1130 mm

•dim. Table: 3350x2130 mm

N°7- anthropomorphic 6-axis robots

N°2+2 blank bundle loading stations at the beginning and end of the line (also loading in Cx2 with double Roland probe)

2000 ton press line tot.

N°1- 1000 ton head press with link drive

•max height: 1518 mm

•min height: 1135 mm

•dim. Table: 3100x2000 mm

N°1- 500 ton end-of-line press

•max height: 1347 mm

•min height: 1140 mm

•dim. Table: 3355x2135 mm

N°1- 500 ton intermediate press

•max height: 1387 mm

•min height: 1195 mm

•dim. Table: 3355x2135 mm

N°4- anthropomorphic 6-axis robots

N°2 blank bundle loading stations at the beginning and end of the line (also loading in Cx2 with double Roland probe)

Clearing 1200 ton.

Mechanical press Clearing 1200 ton

Press bed: 4600 x 2600

Lateral Passage: 1600 mm

Robot: n°1 6-axis robot, capable of transfer handling 420kg

Coil feed line: 1500 mm, maximum capacity 27 tons

Cartesian manipulator for the automated loading of the straps.

Mecfond 600 ton.

Mecfond 600 ton robotic mechanical press

Lateral Passage: 2300mm

Press bed: 3500 x 2280

Robot: n°1 6-axis robot, capable of transfer handling 160kg

Coil feed line: 1300mm width, with a maximum decoiler capacity of 27 tons

Clearing 500 ton.

500 ton mechanical clearing press

Press bed: 3100 x 2100

Side passage: 2000 mm

Complete with 1500mm coil feeder and 27 ton coil reel

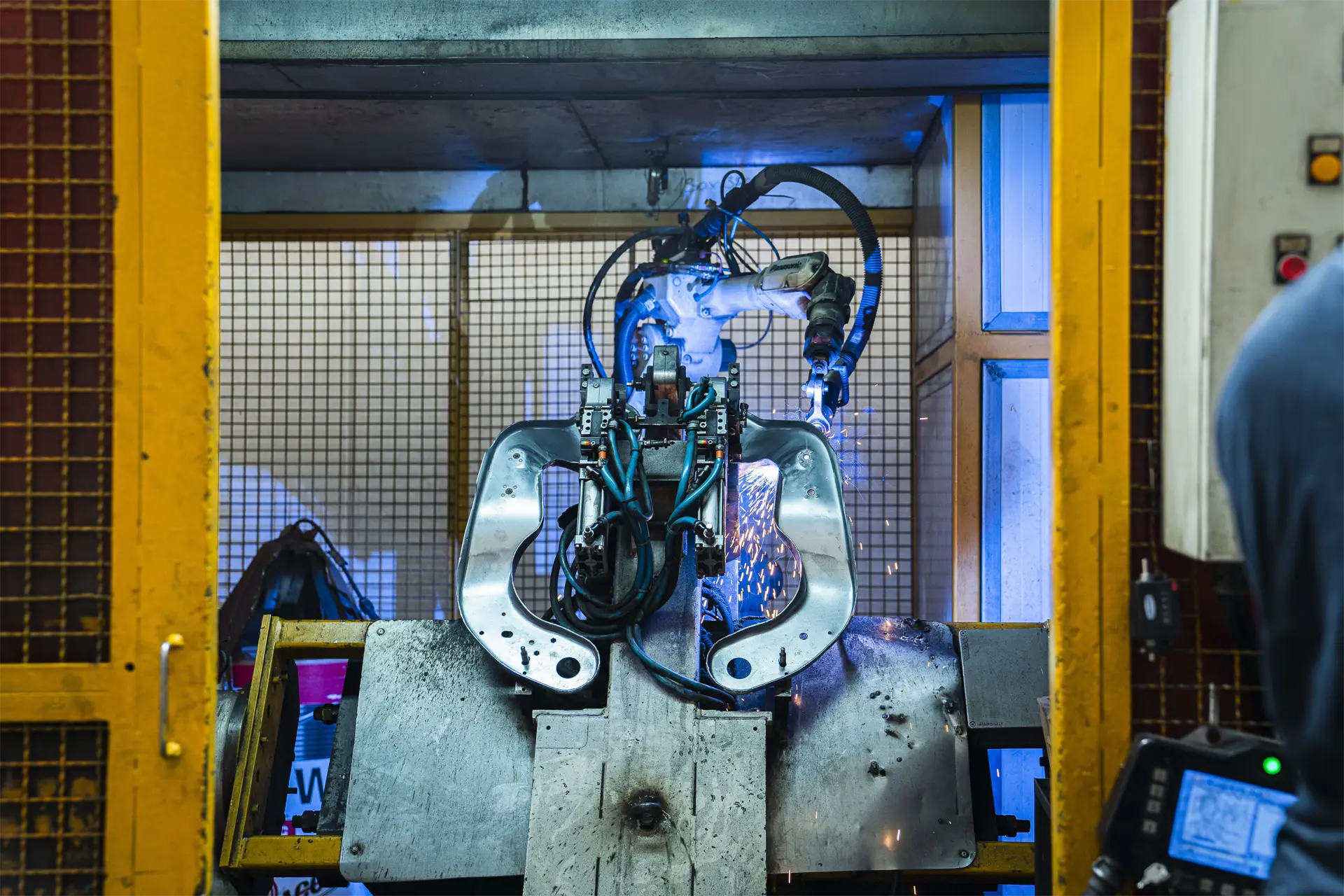

Body in White Department

The Body in White department carries out the final phase of the production cycle before shipment. Where required, stamped parts are further processed by welding small components as specified in the design, such as screws, nuts, and cages, to deliver a finished product.

Robotic welding

Cnc welding

Manual Welding

Maintenance Department

We rely on qualified personnel and a customized management software that allows us to handle all equipment maintenance and machinery maintenance internally through detailed scheduling for both preventive maintenance and extraordinary maintenance reported by Production-Quality. This organization enables us to ensure production continuity, the quality of our products, and the reliability of our supplies

Maintenance management software

All ordinary and extraordinary maintenance is managed by our customized management software, which interactively collects information from production and quality. Additionally, each piece of equipment and machinery has its own specific database, containing all spare part specifications, maintenance plans, and intervention history.

Tool die maintenance

We carry out all preventive ordinary maintenance and extraordinary maintenance internally. Once maintenance is completed, the tool dies are tested under press.

Machinery maintenance

All ordinary and extraordinary maintenance is managed by our customized management software, which interactively collects information from production and quality. Additionally, each piece of equipment and machinery has its own specific database, containing all spare part specifications, maintenance plans, and intervention history.

Tool die and machinery spare parts warehouse

In order to ensure production continuity, we keep all critical spare parts for both tool dies and machinery in stock. Each spare part is assigned a barcode and, through the management software, is linked to the corresponding equipment. The system also manages stock levels and automatically triggers reorder with the supplier.

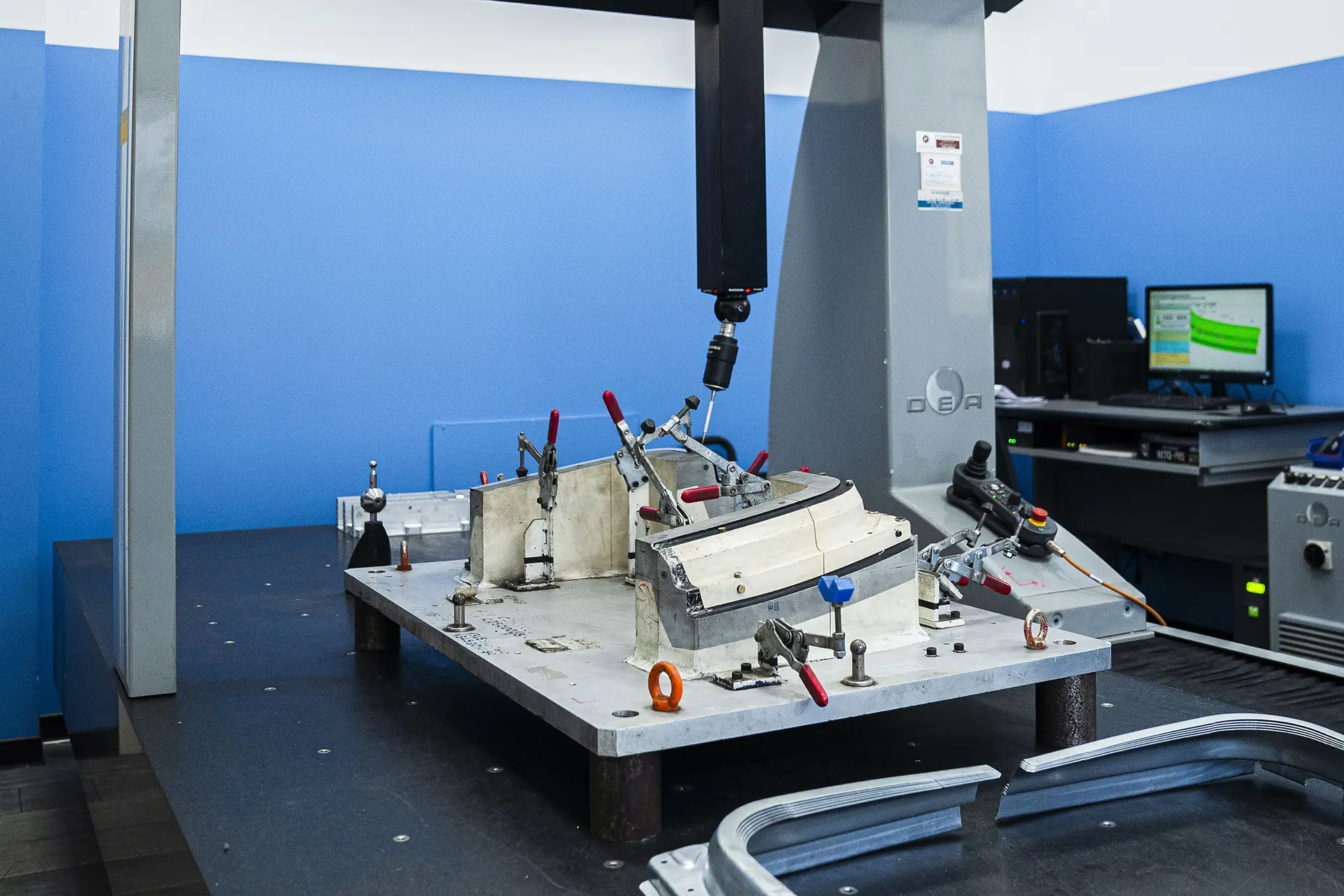

Quality Laboratory

In the current market, the Quality factor holds a primary and increasingly important role. Our quality department relies on state-of-the-art equipment, such as the measuring machine and laser scanners, to ensure component measurements and CP-CPK statistical controls.

Measuring machine cmm - dea global image

Measuring machine cmm – dea global image 12.22.10

* Granite worktable with anti-vibration pneumatic balancing

* Plane dimensions 3180x1400 mm, useful measuring volume 1200x2200x1000 mm

* Motorized automatic structure

* Thermal compensation system

* Point-to-point or continuous measurements (scans)

* Rotating head, complete with a wide range of tip styles/accessories

* PC-DMIS measurement software 2018 rev.

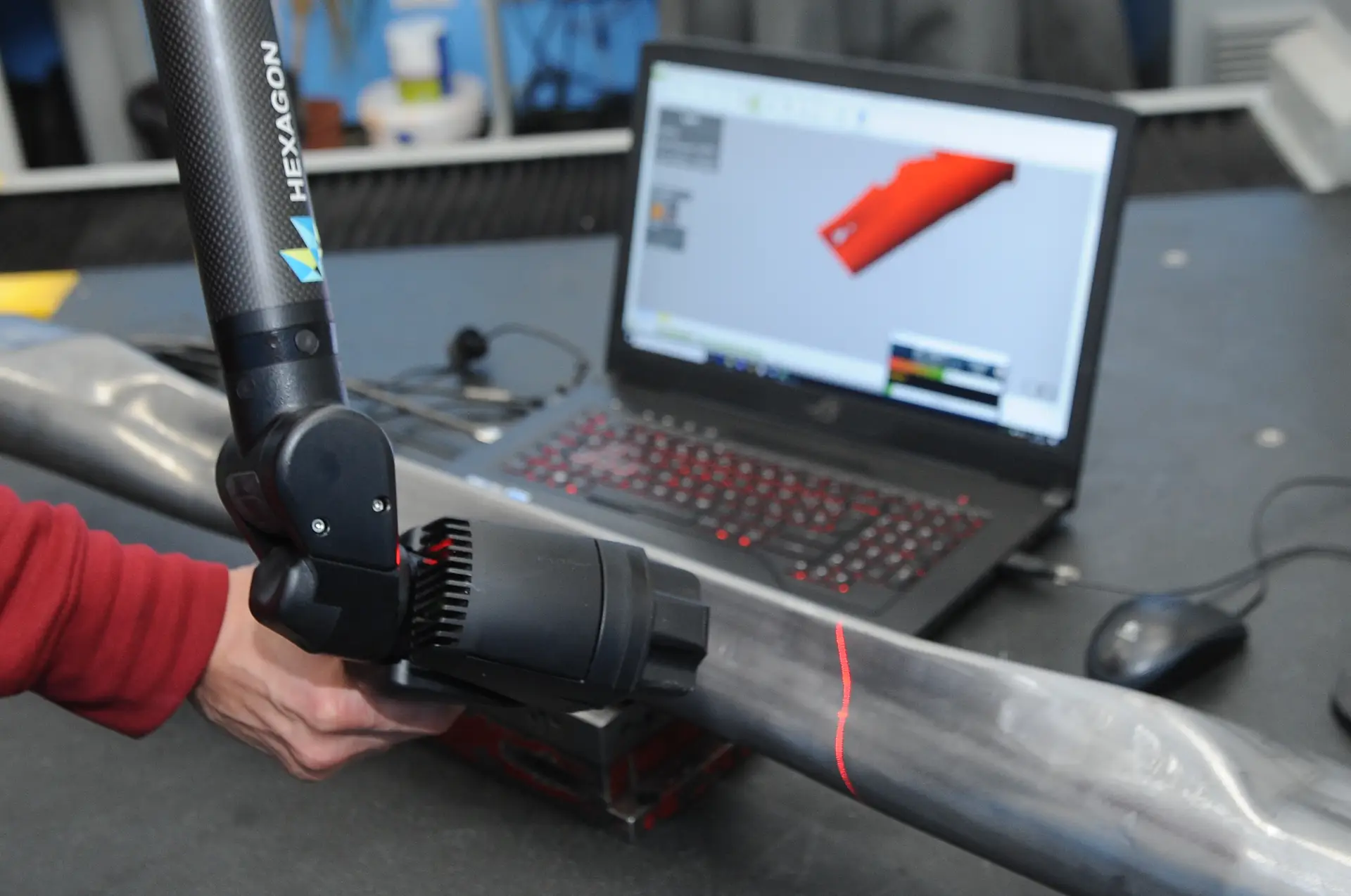

Exagon-absolute arm 7axes

Hexagon-absolute arm 7 axes

*Integrated RS4 scanner with 2.5 m measurement volume

* Zero Gravity counter balance with Smart-Lock

* Absolute encoders

*Digital camera and working light

* B89 certification

* RDS interface software

* Quality control measurement software “ControlX”

* Reverse engineering measurement software “DesignX”

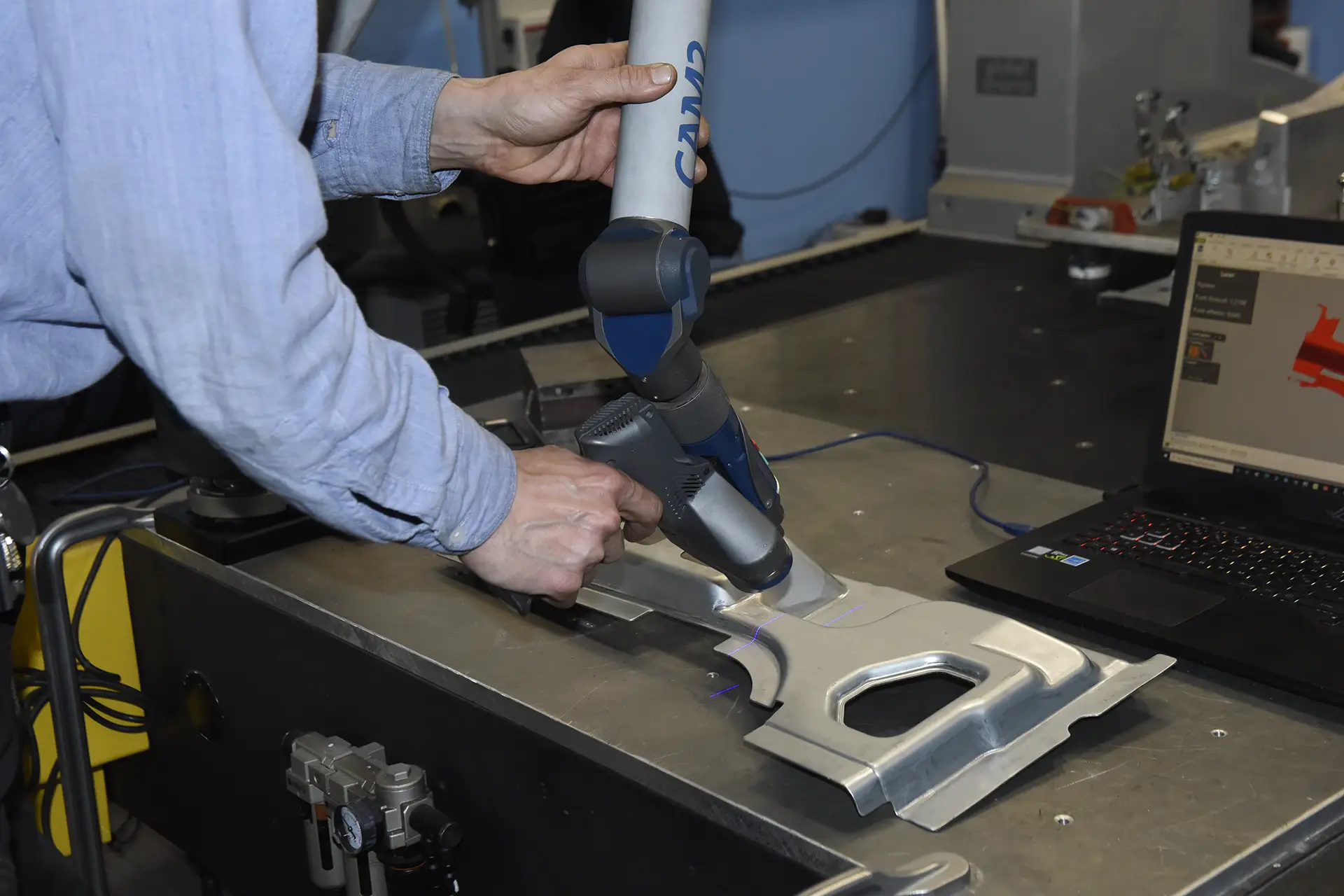

Faro Quantum Scan Arm 7-Axis

Faro Quantum Scan Arm 7-Axis

* Quality control measurement software “ControlX”

* Reverse engineering measurement software “DesignX”

* Wifi connection

* Internal counterbalance system

Logistics

The Logistics department is primarily responsible for storing finished products, following the FIFO (first in, first out) rule and managing JIT (just in time) deliveries. Additionally, it handles the arrival and storage of raw materials.

A high-capacity tow cart is used to move the tool dies planned to be used on the presses.

Contacts

Fill out the form and send a contact request.

Our team of experts will reply to you as soon as possible.